10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Peter Zelinski

Editorial Director, Modern Machine Shop

"Crazy" Tools from Mikron Expand Capabilities

Despite past challenges of the pandemic, Mikron Tool's R&D department runs at full speed, developing efficient machining of demanding materials in the micron range.

Quintus Introduces High-Pressure Warm Forming for Titanium

Quintus Technologies introduces its new process for forming Ti-6Al-4V parts.

For Titanium, Tool Monitoring Smooths Low-rpm Cuts

Caron Engineering’s TMAC MP has been putting tool monitoring to work for years, but its “sawtooth algorithm” now meets a specific challenge in airplane engine machining.

Arcing away from Near-Net Forging

An electrical arc process joins a field of additive manufacturing technologies that could one day provide aerospace manufacturers with alternatives to near-net-shape forgings.

Horn Continues Growth Path

The company highlighted its facility expansions and new cutting tool technologies during a recent open house at its global headquarters in Tübingen, Germany.

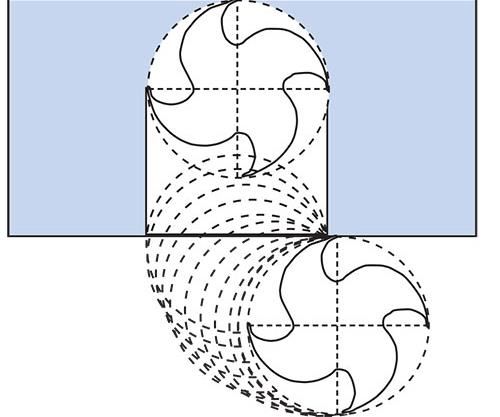

Ultrasonic Technology Poised for Advance into General Machining

Formerly applied only to exotic materials such as ceramics and gemstones, ultrasonic machining has been adapted to more general manufacturing. Titanium and CFRP are two workpiece materials in which the counterintuitive technology shows promise.

.JPG;maxWidth=600;quality=80)